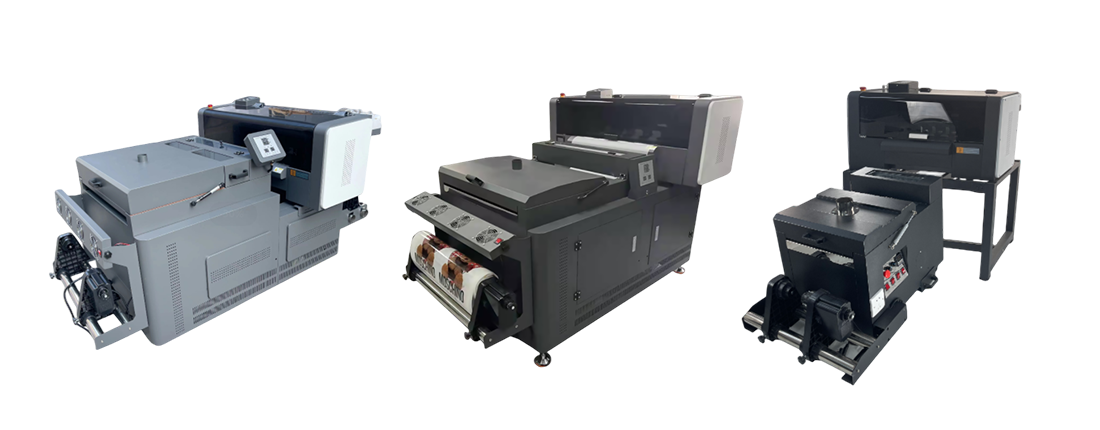

A1/A2/A3

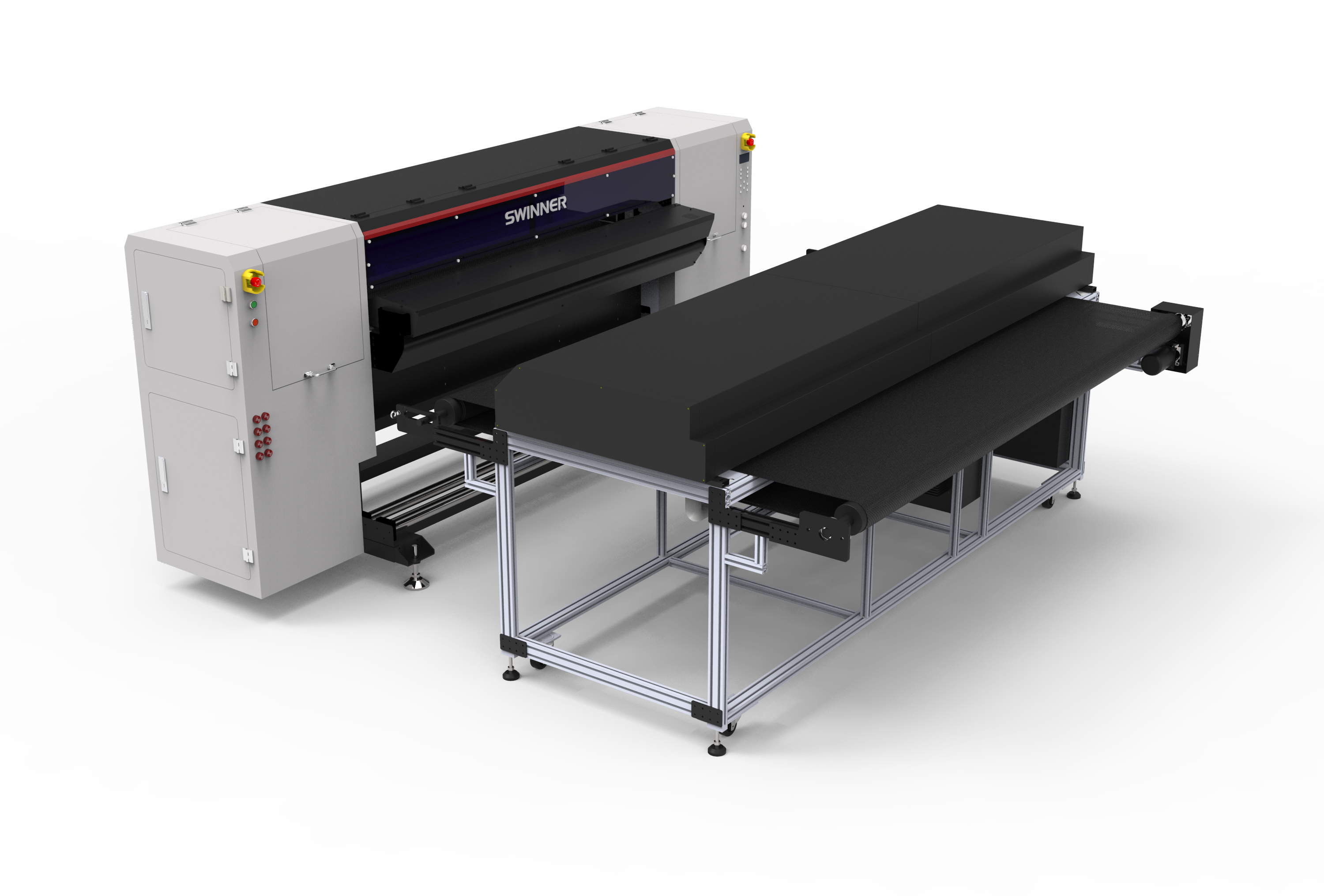

Sprinter DTF printer printing without plate making requirements, as soon as printing, hot stamping without bur, no exposure, soft handle, no fading, strong color fastness, strong tensile strength, no cracking, no requirements on cloth, simple operation process.

Key benefits

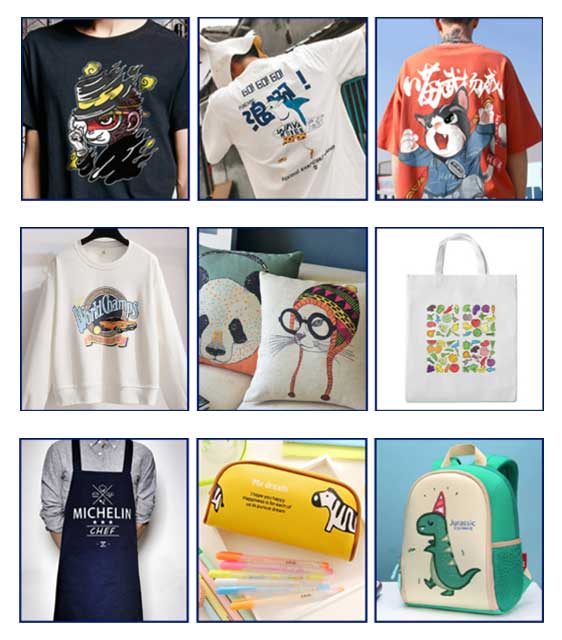

- Applicable to a wide range of materials

- No pre-processing required

- Save white ink

- More durable than DTG printer

- Easy application

- Faster production process

- Helps diversify your inventory

Advantages

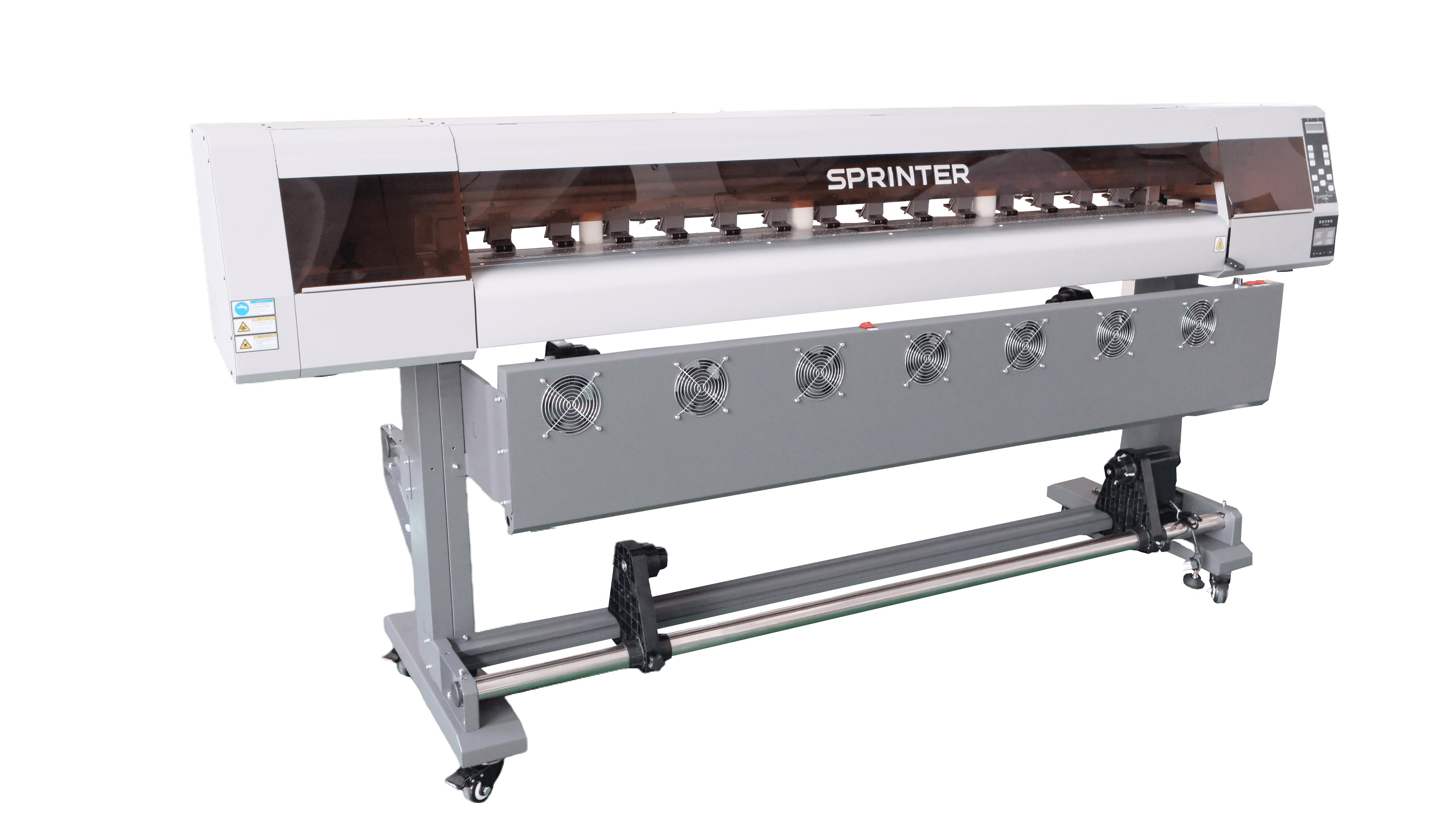

- SPRINTER DTF Printer is more flexible and has a smaller footprint. DTF printer combines printing, powder shaking and baking in one, which is environmental friendly, high printing speed and very stable quality.

- SPRINTER DTF Printer is low cost, bright colors, fastness to more than 3 levels of washing, completely subvert the traditional tedious process of various printing, so as to achieve the advantages of low cost, high efficiency and low loss.

Machine systems

- Printhead maintenance system

- High strength anodizing vacuum adsorption platform

- Ink tank lack detection system

- White ink circulation stirring system

- Automatic height measuring unit

- Automatic load media system

- Powder Shaking control and Powder Spreading control

- Infrared drying system

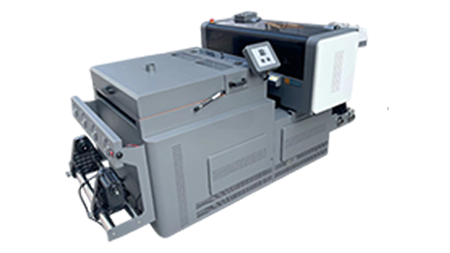

EQUIPMENT

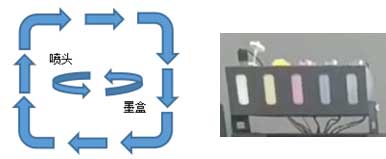

Process Flow

Rich printing solutions, Makes you RICH

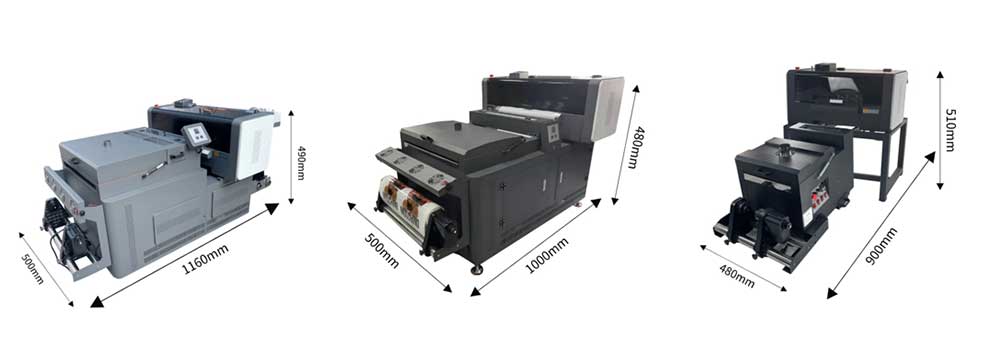

Product dimension diagram

Features

White ink circulation stirring system

A specially designed agitation circulation system for the white ink cartridges allows the white ink to be properly agitated and mixed at all times. White ink is continuously circulated between the white ink cartridge and the printhead, thus reducing white printhead breakage or clogging to ensure that white ink is consistently ejected and printed.

Infrared drying system

Through the infrared heating system, the hot melt adhesive powder and pigment are well combined, and the image after heat transfer is more realistic and the color is more vivid.

Ink tank lack detection system

Automatic large-capacity ink supply system ensures long time printing without interruption. Insufficient ink balance will automatically alarm with an audible sound, and the operator can add ink at any time without affecting normal printing production.

High strength anodizing vacuum adsorption platform

The vacuum adsorption system makes it flat and firmly positioned.

Powder Shaking control and Powder Spreading control

The control of powder shaking and powder spreading can reduce the consumption of hot melt powder and save consumables, and at the same time can make the hot melt powder and the picture more closely, so that the white will not leak during the heat transfer.

Printhead maintenance system

The machine is equipped with printhead moisturizing and automatic cleaning unit to maintain the printhead condition when the equipment is working continuously, while protecting the printhead during non-working periods so that the equipment can be put into use at any time.

Applications

Technical Specs

| Model | A1 A2 A3 | |

| Printhead | Epson i3200/xp600 | |

| Resolution | 360*2400dpi;360*3600dpi;720*2400dpi (4pass;6pass;8pass) | |

| Color | Max. 5; CMYK,W, | |

| Printing size | Maximum Printing Area | 650mm/450mm/330mm |

| Computer (Not included) | Windows 7/10; 64bits | |

| Printing speed | 4pass:10sqm/h; 6pass:6sqm/h;8pass:4sqm/h | |

| Printhead | Max. No.s | 2 |

| Plate | 2 | |

| Software | Control | Sprinter DTF control system |

| RIP | Maitop6.1/photoprint | |

| The ironing temperature | 160-170℃ cold/hot to tear | |

| Color channels | Max. 5; CMYK,W, | |

| Data transfer | USB 3.0 | |

| Electricity | 220V/110V; 50/60Hz; | |

| Machine size & weight | 1160*500*490,69kg;1000*500*480mm,51kg;900*480*510mm,60kg | |

| Packing | Wooden case*1pc; 20’CTNR | |

| Package Size & G.Weight | 1240*690*640mm,69kg;1080*690*640mm,51kg;960*630*620mm,60kg | |

*Specifications subject may change without notice. Please confirm with sales representative for more details